A Complete Guide to Air Compressors in South Africa

An air compressor is a machine that converts power from an engine or motor into potential energy stored in pressurised air. For countless businesses across South Africa, from automotive workshops in Gauteng to large-scale manufacturing plants, these machines are the essential backbone for powering tools and industrial processes efficiently and reliably.

How Does an Air Compressor Work?

The core principle involves four simple steps to create usable compressed air:

Air Intake: The machine draws in ambient atmospheric air through a filter.

Compression: An internal mechanism, typically a piston or a set of rotating screws, rapidly reduces the air’s volume. This decrease in volume causes a significant increase in pressure.

Storage: The newly pressurised air is channelled into a receiver tank for storage, ready for use.

Discharge: When a pneumatic tool is activated, the compressed air is released from the tank, providing the power needed to operate it.

Main Types of Air Compressors

While there are many specialised types, most industrial and commercial needs are met by two primary categories. Choosing the right one is critical for performance and cost-efficiency.

Piston compressors are a common choice for smaller operations. They use a piston moving within a cylinder to compress the air, similar to an internal combustion engine.

Best For: Workshops, garages, and applications with intermittent air demand.

Use Case: Ideal for powering tyre inflators, spray guns, and smaller pneumatic tools.

Key Consideration: Not designed for 24/7 continuous operation.

For heavy-duty industrial applications, rotary screw compressors are the industry standard. They use two interlocking helical screws (rotors) that trap and compress air as they turn.

Best For: Manufacturing, construction, and any business requiring a constant, reliable air supply.

Use Case: Powers assembly lines, industrial machinery, and large construction equipment.

Key Advantages: Generally quieter, more energy-efficient, and built for a longer operational lifespan with lower maintenance needs compared to piston models.

Common Uses for Air Compressors Across Industries

A single air compressor can power a vast range of tools and processes, making it a versatile asset for any business:

Automotive: Powering impact wrenches, lifts, and spray-painting equipment.

Manufacturing: Operating automated machinery on assembly and packaging lines.

Construction: Driving jackhammers, nail guns, and concrete breakers.

Agriculture: Operating crop sprayers, irrigation systems, and pneumatic tools for maintenance.

The Titan Emporium Advantage: Service & Expertise

Choosing the right compressor is more than just a purchase; it’s an investment in your business’s productivity.

Expert Advice: We help you select the correct type and size for your specific operational needs.

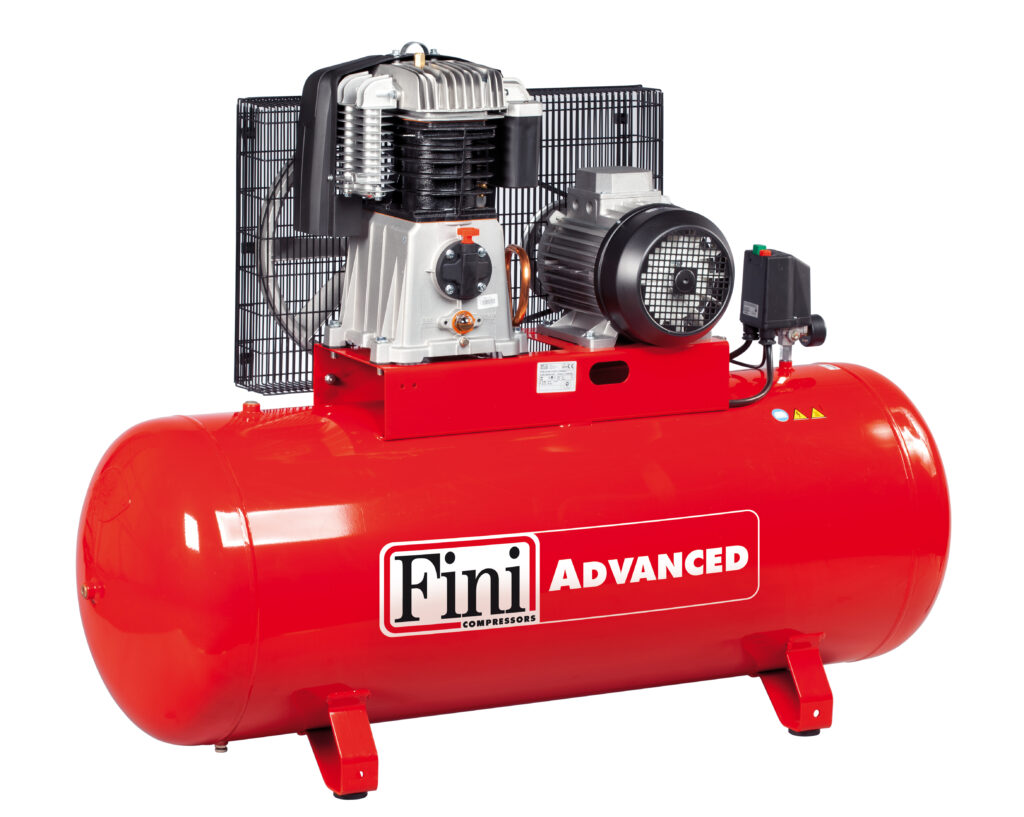

Leading Brands: We supply everything from our affordable Budget Air range to premium European brands like FINI.

After-Sales Support: Our service includes reliable repairs, scheduled maintenance, and a full inventory of spare parts to minimise downtime.

Comprehensive Warranties: We stand by our products, offering long warranties, including a 5-year air end warranty on our rotary screw compressors.

Frequently Asked Questions

What size air compressor do I need?

The right size depends on the tools you need to power. Check the Cubic Feet per Minute (CFM) requirement of your most demanding tool and choose a compressor with a higher CFM rating to ensure adequate power. Our team can help you calculate your exact needs.

How often does an air compressor need to be serviced?

Service frequency depends on the type of compressor and its usage. For heavy-duty rotary screw compressors, regular maintenance checks are crucial. We offer tailored service agreements to keep your machine running optimally.

Are compressed air tools better than electric ones?

Compressed air tools are often lighter, more powerful, and have fewer moving parts, making them more durable and easier to maintain than their electric counterparts.